What is plywood?

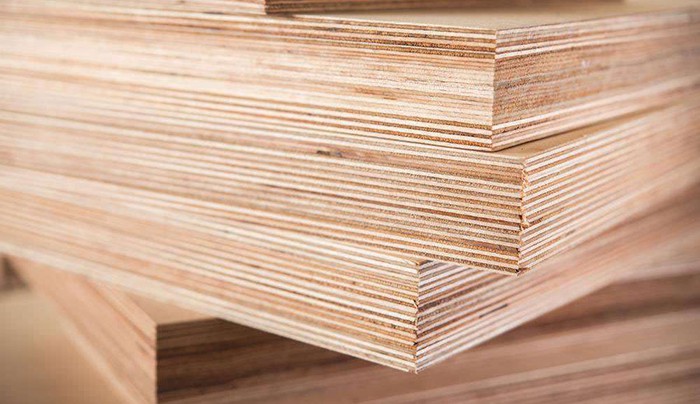

Plywood is often referred to as laminated wood or glued wood. This is precisely the term used to refer to wood sheets that are glued together with multiple layers of natural wood. They are stacked together and bonded with specialized adhesive.

Currently, industrial engineered wood products such as HDF and MDF are widely used. Especially in the market, Plywood has emerged with its excellent properties. So what exactly is Plywood and how is this material utilized? Let's explore together in the article below!

1. What is Plywood?

Plywood is often referred to as laminated wood or glued wood. This is precisely the term used to refer to wood sheets that are glued together with multiple layers of natural wood. They are stacked together and bonded with specialized adhesive.

1.1. Structure of Plywood Sheets

The structure of plywood sheets can be easily distinguished. Each plywood sheet is made with a thickness ranging from 1-5 mm. They have the same size in both thickness and length. In between, a layer of specialized adhesive is used to bond perfectly. Typically, to bond natural wood sheets into plywood, Phenol or Formaldehyde adhesive is used.

1.2. Characteristics of Plywood

The characteristics of Plywood are always of interest to customers when exploring this special material. Simply put, Plywood sheets are created from thin natural wood pieces, pressed by professional industrial machines.

The number of wood pieces used to press the plywood sheet is usually odd, such as 3, 5, 7, depending on the usage requirements. To explain this principle is quite easy. The odd number of layers is to harmonize the color of the two outer plywood layers with similar wood grain, enhancing the beauty of the wood piece.

1.3. Plywood Manufacturing Process

When exploring what Plywood is, you can refer to the simplest Plywood manufacturing process to understand more about this material. Below is the simplest Plywood manufacturing process!

- Step 1: Peel the wood bark and cut the wood pieces to the desired size.

- Step 2: Feed the wood into a cutting machine to create thin wood sheets.

- Step 3: Place the thin wood sheets on a conveyor to cut into required sizes and separate into different types.

- Step 4: Dry the wood sheets in a drying machine to reach the specified moisture content.

- Step 5: Use scanning technology to check for defects on the wood sheets and then proceed to fix the defects.

- Step 6: Clean the thin wood and evenly coat both sides of the plywood sheet with adhesive. Stack them together according to the required thickness.

- Step 7: Put the plywood sheet into a cold press to flatten.

- Step 8: Transfer the plywood sheet to a hot press for a specified time to tightly bond the thin wood sheets together.

- Step 9: Cool the plywood sheet and put it into a trimming and sanding machine to trim the edges and smooth the surface.

- Step 10: Quality check the finished product according to the Plywood production process.

2. Types of Plywood Wood Nowadays

- Plywood from adhesive wood:

Plywood from adhesive wood, also known as Adhesive Plywood or adhesive veneer. Adhesive wood is a type of wood commonly used for plywood production due to its versatility and availability. It is made by bonding together small wood pieces with adhesive, forming a strong and durable material. Adhesive plywood is widely used in various construction and furniture projects due to its strength and stability.

- Plywood from birch wood:

Plywood from birch wood, also known as Birch Plywood. Birch wood is a popular choice for plywood due to its fine grain and uniform texture. Birch plywood is commonly used in furniture manufacturing, cabinetry, and interior design projects. It is prized for its attractive appearance, durability, and ease of machining. Birch plywood comes in a variety of grades and finishes, making it suitable for a wide range of applications.

- Plywood from oak wood:

Plywood from oak wood is obtained from the oak tree, pieced together to form a large piece of wood, then glued onto the wood core. This material is aesthetically pleasing with extremely unique colors and beautiful swirling patterns. Nowadays, consumer trends favor the colors of Oak Plywood. Plywood from oak wood comes in various wood grains such as Ballad Laminates, Catania Laminates, Melamine...

- Plywood from poplar wood:

Plywood from poplar wood, also known as Poplar Plywood or poplar veneer. This is a common fine-grained wood. Poplar Plywood is one of the most common materials used in house construction or in the production of wooden furniture such as cabinets, chairs, desks, shelves... This type of plywood has many aesthetic advantages. It has a beautiful gloss, elegant appearance, suitable for interior decoration.

- Plywood from white oak wood:

Plywood from white oak wood is one of the commonly used materials in construction in Europe. They are durable, with a luxurious and elegant surface color. Unlike oak wood, white oak Plywood has a unique and original color. However, the production cost of plywood from white oak wood is quite high compared to other natural woods.

- Plywood from ash wood:

Plywood from ash wood, also known as Ash Plywood. Ash wood, also known as olive wood, originates from Eastern Europe and North America. This material has excellent load-bearing capacity and is easy to bend, so it is often used for kitchen cabinets, sofas, wooden doors... The lifespan of plywood from ash wood is quite high, so they are favored by customers.

3. Pros and Cons of Plywood

When researching what Plywood is, you can analyze the pros and cons of Plywood to know more detailed information.

Pros:

- Excellent moisture resistance. You can soak Plywood in water for 3 days without damage or swelling.

- Due to the use of natural wood pieces to create Plywood, they are quite durable, rarely swelling.

- Plywood has advantages in hardness and durability compared to other industrial wood types. Plywood resists warping effectively, suitable for long-term use.

- Plywood has excellent screw adhesion when assembling items such as bathroom cabinets, study tables, etc.

- Easy to coat with different types of paint to enhance the aesthetics of furniture.

- Plywood is environmentally friendly, does not contain additional harmful plastics and additives.

Cons:

- Plywood is more expensive than industrial wood panels such as MDF, HDF, MFC.

- Less diverse in colors compared to other industrial wood types.

4. Applications of Plywood in Life

- Plywood is used in many civil construction projects and residential buildings due to its high durability. With good waterproof properties, Plywood is used as formwork for pouring concrete, floor underlay when laying house floors, or wall cladding.

- Plywood is most commonly used in producing indoor furniture items. With the advantages of hardness, durability, and good load-bearing capacity, Plywood is utilized to make house floors, wooden ceilings, partition walls... In addition, indoor furniture items requiring high waterproofing such as tables, chairs, beds, shelves...

- Enic applies the advantages of Plywood and overcomes its disadvantages to produce high-end smart bathroom cabinets. With high durability and waterproofness, Plywood is very suitable for use as bathroom fixtures.

Above are all the information about what Plywood is for you to gain more knowledge about this special material. From there, you can confidently choose furniture items, sanitary equipment in your home made from Plywood.