How to Distinguish High Quality and Low Quality Peeled Boards

Peeled board is an indispensable material in furniture production thanks to its aesthetics and reasonable cost. The market is diverse in quality, making it difficult for consumers to choose. To choose quality veneer, you need to pay attention to the wood material, thickness, color and grain to ensure aesthetics and durability.

1. Wood Material

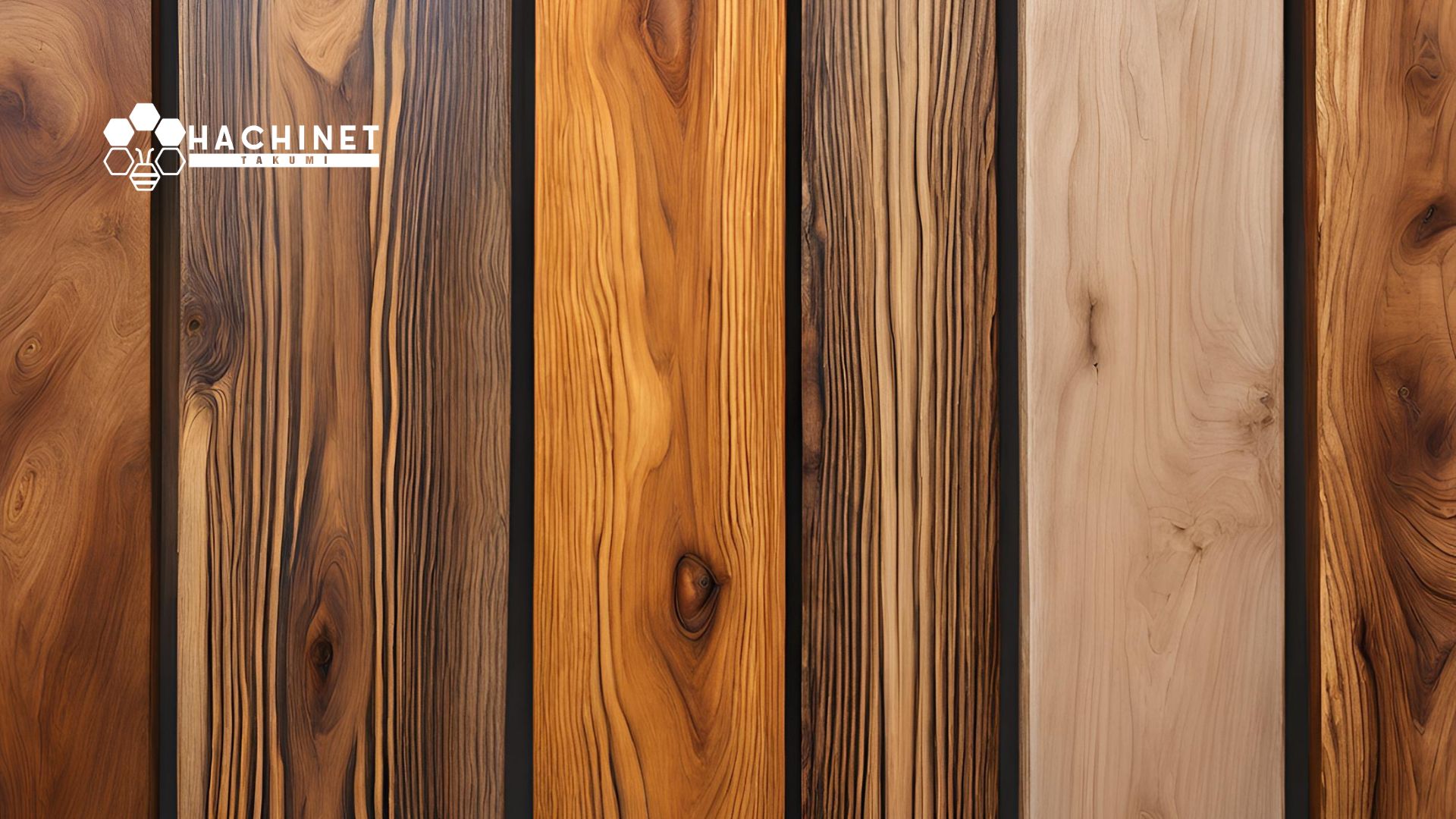

High quality veneer is often produced from precious woods such as oak, walnut, teak and pine. The common characteristics of these types of wood are beautiful natural colors and clear wood grain, creating luxury for interior surfaces. More importantly, these types of wood are carefully selected from responsible sources, ensuring no defects such as knots, cracks or pests.

On the contrary, low-quality peeled boards are often made from poor quality woods or without a clearly identifiable origin. These types of wood often have uneven colors, often have patchy spots and unclear wood grain. In addition, the quality of wood is not guaranteed with many defects such as holes and cracks, easily causing problems with engine durability and product aesthetics.

2. Thickness and Uniformity

The thickness and uniformity of high-quality veneer is important to ensure the aesthetics and durability of the final product. High quality peeled boards usually have uniform thickness from head to tail, with no significant difference between positions on the board. This not only makes machining and installation easier, but also prevents problems such as blistering and deformation after the product is used in high humidity environments.

In contrast to high quality peeled boards, low quality peeled boards often have differences in thickness on the same board. This can cause major problems during machining and installation, especially when boards of a certain thickness are needed to meet design requirements.

3. Color and Wood Grain

The color of high-quality peeled boards is usually natural and uniform, without spots or major color changes after use. Wood grain on the surface of peeled boards is often very clear and beautiful, helping to add aesthetics and esthetic value to the interior.

On the contrary, low quality peeled boards often have uneven colors and are prone to fading quickly. Wood grain on the surface is often unclear, may be blurred or uneven, causing unwanted aesthetic changes to the final product.

4. Surface Treatment and Durability

The surface of high-quality peeled boards is usually smooth and free of scratches or roughness. This not only helps increase aesthetics but also makes application and use easier. In particular, high-quality peeled boards often have better water resistance, helping to avoid problems of blistering or deformation when exposed to wet environments.

On the contrary, low-quality peeled boards often have a surface that is not thoroughly treated and may have scratches, roughness and many other defects. This not only reduces the aesthetics of the product but also leads to ineffective use of the product over a long period of time.

Distinguishing and selecting high-quality and low-quality veneer is an important process to ensure the aesthetics and durability of interior products. When choosing veneer, always pay attention to factors such as wood material, thickness, color and grain, surface treatment and durability to get the product that best suits your needs and expectations