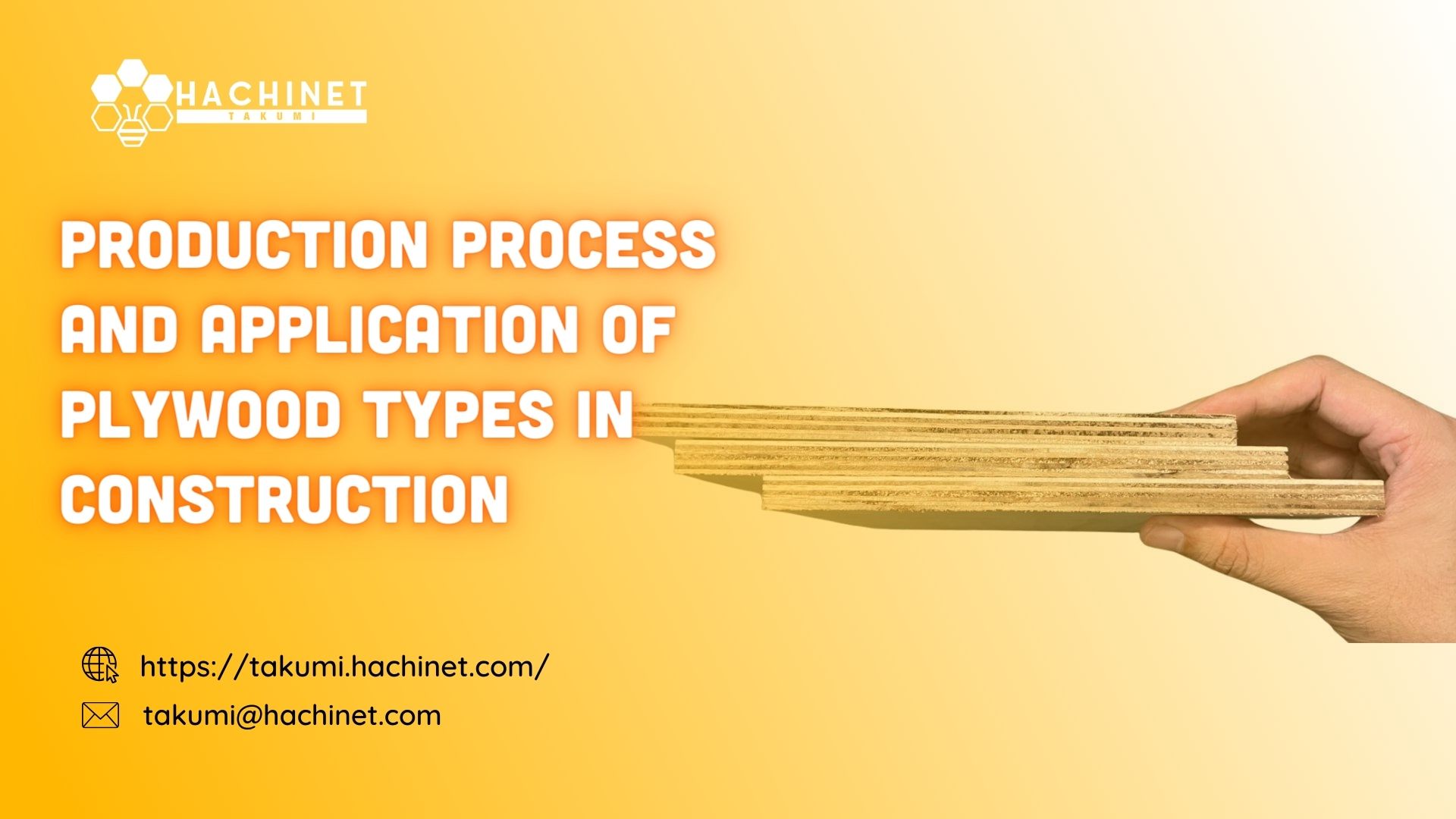

Unveiling the Market Analysis of Plywood Manufacturing Industry in Vietnam

In recent years, Vietnam has emerged as a key player in the global plywood manufacturing industry, leveraging its abundant natural resources, skilled workforce, and strategic location to establish itself as a leading exporter of plywood products. This comprehensive market analysis delves into the dynamics shaping the plywood manufacturing sector in Vietnam, exploring key trends, challenges, and opportunities for stakeholders across the value chain.

Overview of Vietnam's Plywood Manufacturing Industry

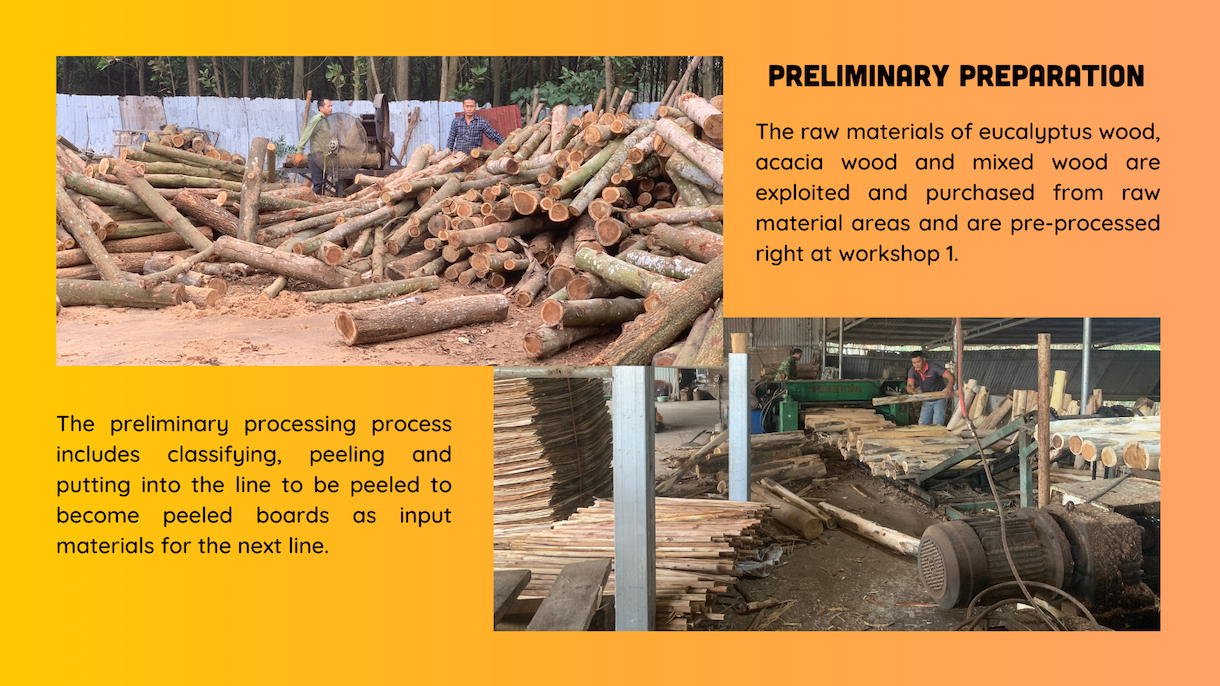

Vietnam's plywood manufacturing industry has witnessed significant growth in recent years, fueled by robust demand from both domestic and international markets. The country's abundant supply of raw materials, including high-quality timber species such as acacia, eucalyptus, and rubberwood, provides a competitive advantage for plywood producers. Additionally, Vietnam's strategic location within Southeast Asia enables easy access to key export markets, further bolstering the industry's growth prospects.

Market Trends and Growth Drivers

Several factors contribute to the growth of Vietnam's plywood manufacturing industry, including:

Rising Demand for Plywood Products: The construction, furniture, and packaging industries are major consumers of plywood products, driving demand both domestically and internationally.

Increasing Export Opportunities: Vietnam's plywood exports have been on the rise, fueled by growing demand from key markets such as the United States, Japan, and the European Union.

Technological Advancements: Plywood manufacturers in Vietnam are increasingly adopting advanced technologies and production processes to enhance efficiency, improve product quality, and reduce environmental impact.

Government Support: The Vietnamese government has implemented policies and initiatives to support the development of the plywood manufacturing sector, including investment incentives, infrastructure development, and regulatory reforms.

Challenges Facing the Industry

Despite its promising growth prospects, Vietnam's plywood manufacturing industry also faces several challenges, including:

Raw Material Supply Constraints: Ensuring a sustainable supply of raw materials is a key challenge for plywood manufacturers, particularly amid concerns about deforestation and environmental sustainability.

Competition from Other Materials: Plywood faces competition from alternative materials such as particleboard, medium-density fiberboard (MDF), and engineered wood products, which offer comparable properties at potentially lower costs.

Quality Control and Compliance: Maintaining consistent product quality and compliance with international standards is essential for plywood manufacturers to remain competitive in global markets.

Market Volatility: Fluctuations in global market conditions, including changes in demand, currency exchange rates, and trade policies, can impact the profitability of plywood manufacturers.

Opportunities for Growth and Expansion

Despite the challenges, Vietnam's plywood manufacturing industry presents numerous opportunities for growth and expansion, including:

Diversification of Product Portfolio: Plywood manufacturers can explore opportunities to diversify their product portfolio by offering value-added products such as veneer-faced plywood, marine plywood, and specialty plywood products tailored to specific end-user requirements.

Market Penetration: Expanding into new domestic and international markets, particularly emerging economies in Asia and Africa, can help plywood manufacturers tap into new sources of demand and reduce reliance on traditional export markets.

Investment in Research and Development: Investing in research and development (R&D) to develop innovative products, improve production processes, and enhance sustainability can provide a competitive edge for plywood manufacturers in Vietnam.

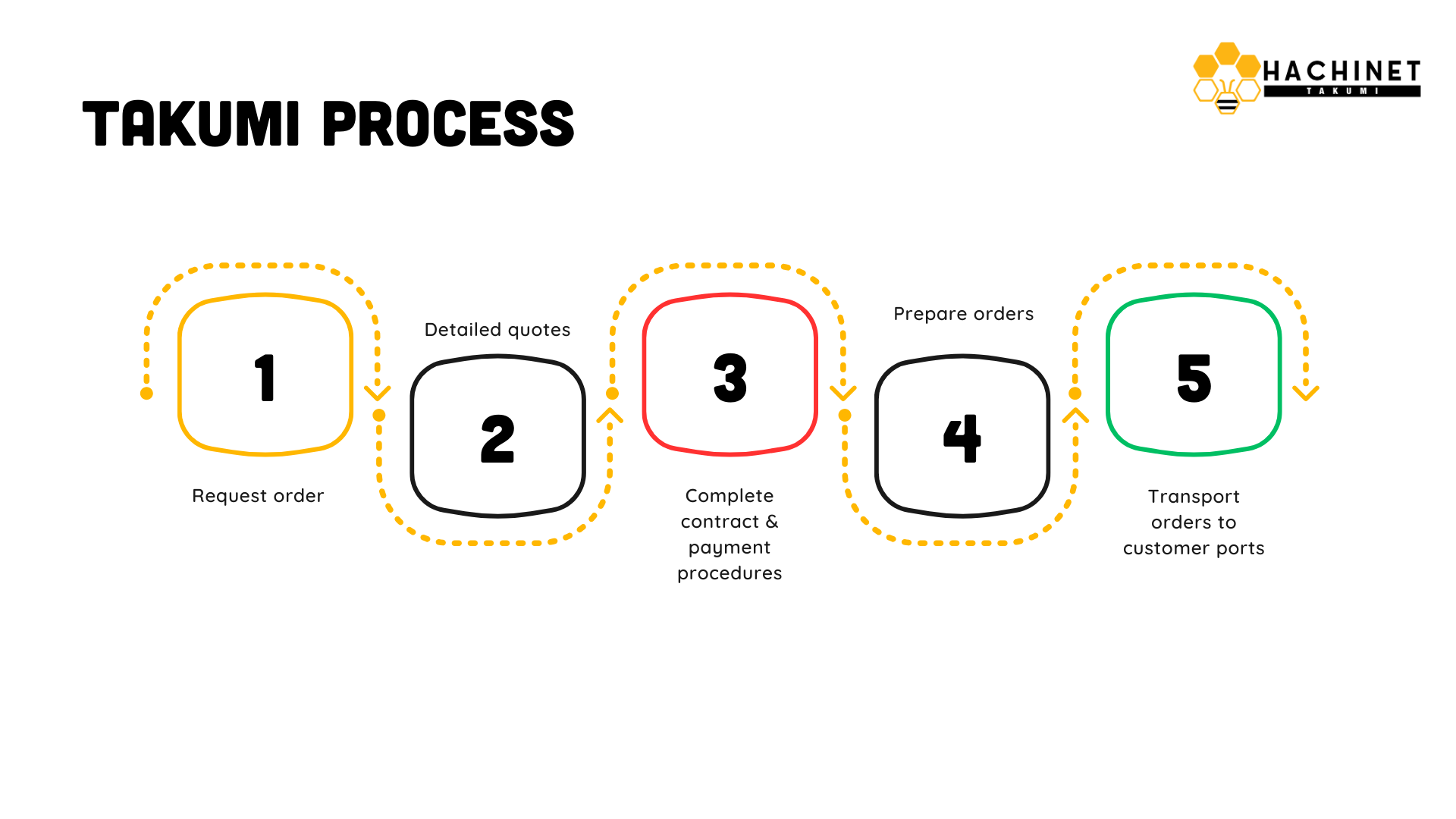

Collaboration and Partnerships: Collaborating with stakeholders across the value chain, including raw material suppliers, technology providers, and distribution partners, can help plywood manufacturers access new resources, expertise, and market opportunities.

In conclusion, Vietnam's plywood manufacturing industry presents a dynamic landscape characterized by growth, innovation, and evolving market dynamics. While facing challenges such as raw material supply constraints and market volatility, plywood manufacturers in Vietnam are well-positioned to capitalize on opportunities for growth and expansion. By embracing technological advancements, enhancing product quality, and exploring new market opportunities, Vietnam's plywood manufacturing industry is poised to remain a key player in the global plywood market for years to come.