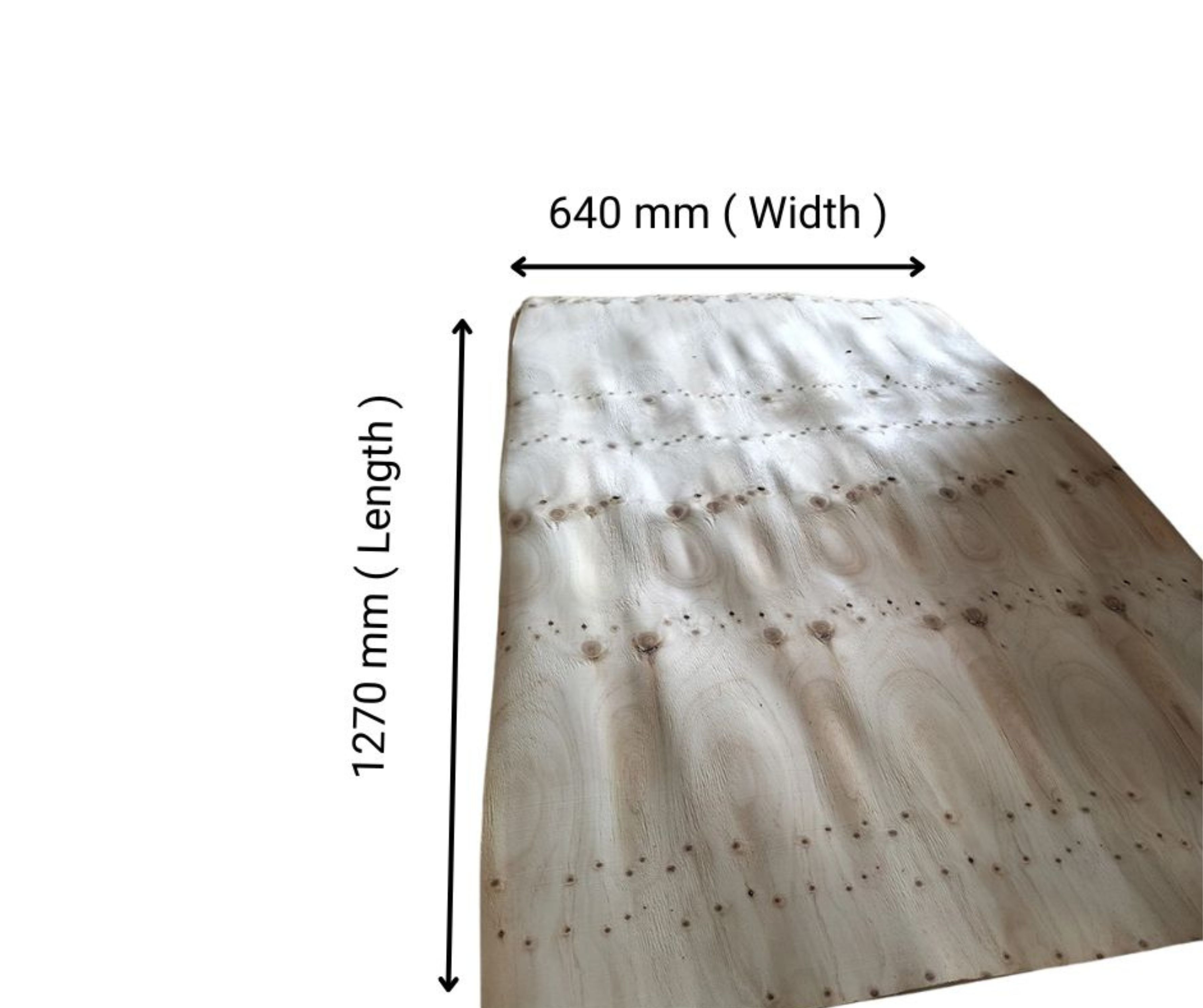

Pine Veneer

Specifications:

– Dimensions (Length x Width): 1270mm x 640mm

– Thickness: 1.7mm ~ 2mm

– Tolerance: 0~0.05 mm

– Quality: 100% A, 90% A 10% B

– Moisture: 20%~25%

– Packaging: 1600~1700 bundles/container 40ft

– Quantity: 40HC container, 40ft container, 20ft container

– Payment method: TT, L/C

– Quotation method: CNF, CIF, FOB

– Ability supply: 50 x 40ft/month

- Origin port: Haiphong, Vietnam

Pine wood is a soft wood with a hard-to-distinguish core, light yellow wood grain, straight round trunk, suitable for peeling boards. Carefully treated pine boards will adapt well to humid environments, limiting shrinkage and warping. Vietnamese Pine Veneer is crafted from high-quality pine trees indigenous to Vietnam's forests. Known for its light color and smooth texture, this veneer lends a natural and rustic charm to woodworking projects. Vietnamese Pine Veneer is favored for its affordability and versatility, making it ideal for a wide range of applications in furniture making, interior design, and architectural projects. With sustainable forestry practices in place, Vietnamese Pine Veneer offers an eco-friendly option for enhancing spaces with its timeless beauty and warmth.

The process of producing Pine Veneer involves several stages:

Log Selection: High-quality Pine logs are chosen based on their size, straightness, and absence of defects.

Log Preparation: The selected logs are debarked and prepared for slicing or peeling. This may involve soaking the logs to soften them for easier cutting.

Slicing or Peeling: The prepared logs are sliced into thin sheets using a veneer slicer or peeled using a rotary lathe. Slicing produces flat-cut veneer, while peeling results in rotary-cut veneer, each with its own distinct appearance.

Drying: The freshly cut veneer sheets are dried in a controlled environment to remove moisture and stabilize the wood. Proper drying is essential to prevent warping or cracking.

Grading: The dried veneer sheets are graded based on their quality, considering factors such as grain pattern, color consistency, and surface defects.

Trimming and Sanding: Veneer sheets may undergo further trimming and sanding to achieve uniform thickness and smoothness.

Finishing: Depending on the desired application, the veneer may be finished with stains, sealants, or coatings to enhance its appearance and protect the wood.

Packaging: The finished veneer sheets are packaged and prepared for distribution to manufacturers or customers.

Throughout the production process, strict quality control measures are implemented to ensure that the Acacia veneer meets industry standards and customer expectations for appearance and performance.

Contact for consultation/order

Contact for consultation/order