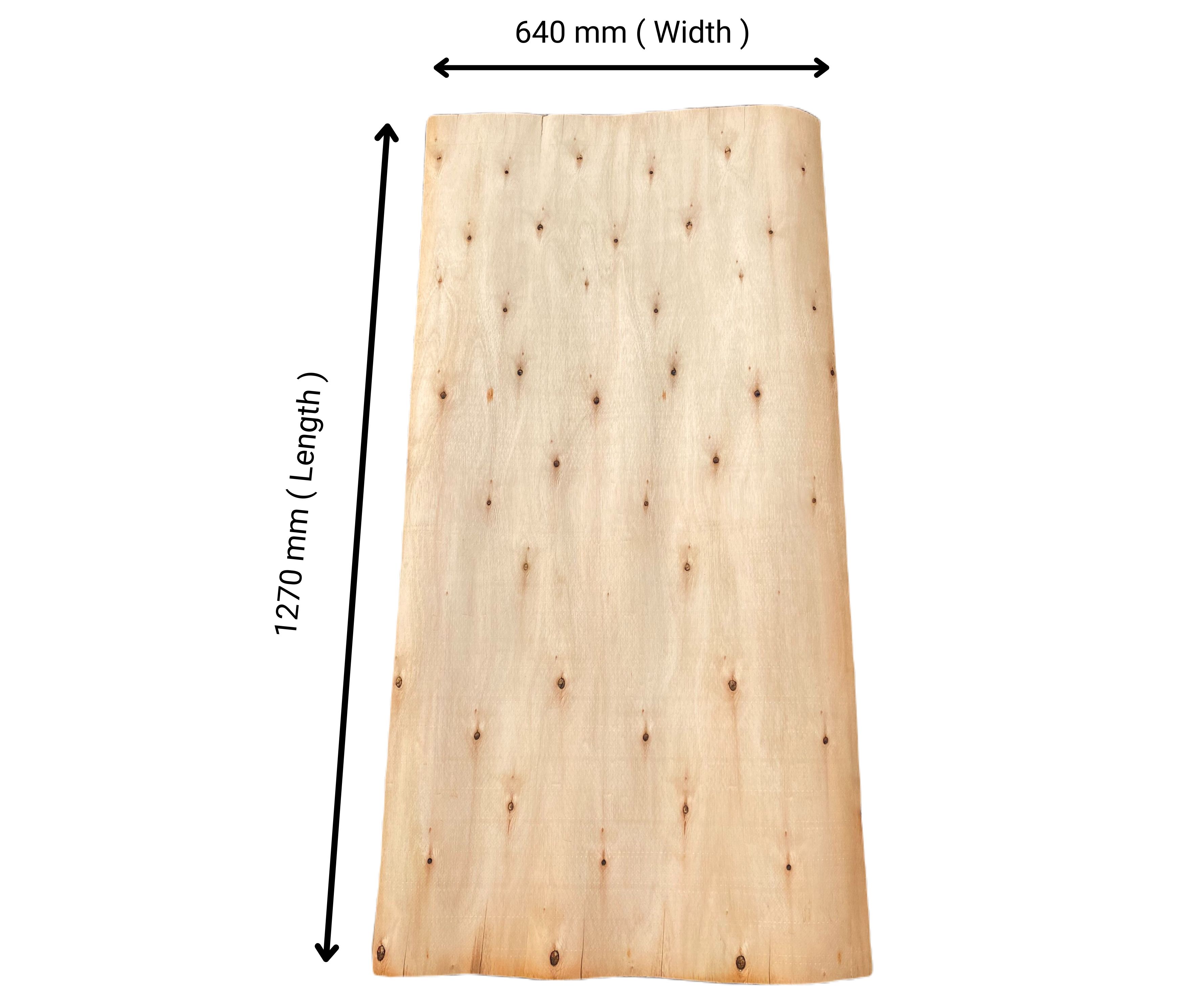

Eucalyptus Veneer

Specifications:

– Dimensions (Length x Width): 1270mm x 640mm

– Thickness: 1.7mm ~ 2mm

– Tolerance: 0~0.05 mm

– Quality: 100% A, 90% A 10% B

– Moisture: 20%~25%

– Packaging: 1600~1700 bundles/container 40ft

– Quantity: 40HC container, 40ft container, 20ft container

– Payment method: TT, L/C

– Quotation method: CNF, CIF, FOB

– Ability supply: 50 x 40ft/month

- Origin port: Haiphong, Vietnam

Eucalyptus trees can adapt to barren places, poor nutrients, and harsh conditions, so they are easy to grow. Their growth period is short, so they can be exploited after only 5-7 years. This type of wood is quite hard, strong and heavy. However, eucalyptus wood dries quickly and easily warps.

Producing eucalyptus veneer involves several key steps:

1. Log Selection: High-quality eucalyptus logs are selected based on their size, straightness, and absence of defects.

2. Log Preparation: Logs are debarked and prepared for slicing or peeling. This process may involve soaking the logs in water to soften them for easier cutting.

3. Slicing or Peeling: The prepared logs are sliced into thin sheets using a veneer slicer or peeled using a rotary lathe. Slicing produces flat-cut veneer, while peeling results in rotary-cut veneer, each with its own unique appearance.

4. Drying: The freshly cut veneer sheets are dried in a controlled environment to remove moisture and stabilize the wood. Proper drying is crucial to prevent warping or cracking.

5. Grading: The dried veneer sheets are graded based on their quality, including factors such as grain pattern, color consistency, and surface defects.

6. Trimming and Sanding: Veneer sheets may undergo additional trimming and sanding to achieve uniform thickness and smoothness.

7. Finishing: Depending on the desired end use, the veneer may be finished with stains, sealants, or coatings to enhance its appearance and protect the wood.

8. Packaging: The finished veneer sheets are packaged and prepared for distribution to manufacturers or customers.

Throughout the process, careful attention is paid to quality control to ensure that the eucalyptus veneer meets industry standards and customer expectations.

Contact for consultation/order

Contact for consultation/order